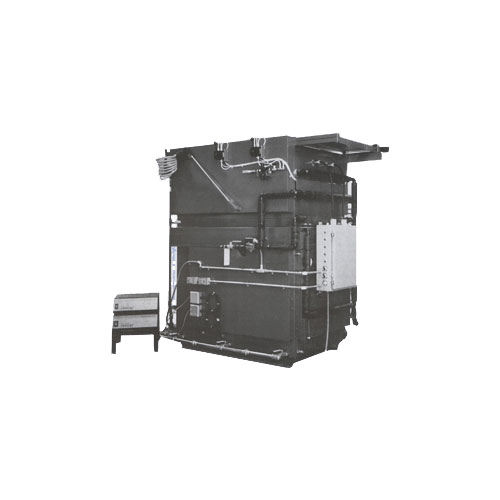

Product

SDA

OPTIONAL EQUIPMENT

- EXHAUST BLOWER including motor and magnetic starter mounted on machine

- WATER REMOVER Necessary when removing soluble oils

- LOW-SOLVENT CUT OUT added and possible solvent breakdown

- WATER REGULATOR throttling valve conserves cooling water and reduces sweating

- ULTRASONICS

- FLOW SWITCH AND STRAINER for condenser water

- HIGH TEMP LIMIT for condensor water

- POWERED COVERS Air operated and bi- parting for model 48 and larger

STANDARD EQUIPMENT

- “COOL ZONE” Freeboard Chilling And Closed Circuit Vapor Line Control.

- Stainless Steel Vapor Tank

- Insulation On Sides And Bottom

- Self Distilling

- Combination Spray / Drain Pump With Foot Switch

- Portable Stainless Steel Heaters

- Large Clean Out Ports

- Vapor Level Safety Switch

- Lip Vent Exhaust Duct W / O Blower

- Boiling Chamber High Temp Limit Switch

- Bi – Parting Sliding Covers

- ”Vapor Up” Thermostat

- Easily Adjusted To Use Trichlorethylene Or

- Perchlorethylene

- Nema 12 Control Box

- Warning Lights With Switches To indicate :

– Low Solvent

– Clean – out Time

– Water Or Vapor Line Control Failure

Heaters Are individually Fused and Switched .Loss of One Heater does not completely disable Machine And interrupt production .

| Model # | A | B | C | D | E | F | CAPACITY LBS/HR STEEL |

HEAT | SOLVENT CAPACITY | SHIPPIN WEIGHT |

|||

| TRI | PER | G | H | I | |||||||||

| 36 36 A 48 48 A 48 B 60 |

18 18 24 24 24 30 |

18 24 24 24 24 24 |

12 12 18 18 24 24 |

60 60 76 76 76 93 |

34 40 40 40 40 40 |

46 52 58 58 64 64 |

1500 1500 1500 2000 2000 2000 |

1000 1000 1000 1400 1400 1400 |

12KW 12KW 12KW 20KW 20KW 20KW |

15 20 25 25 25 30 |

22 28 55 55 75 90 |

15 20 25 25 25 30 |

1000 1200 1500 1800 1800 2400 |

wordpress theme powered by jazzsurf.com